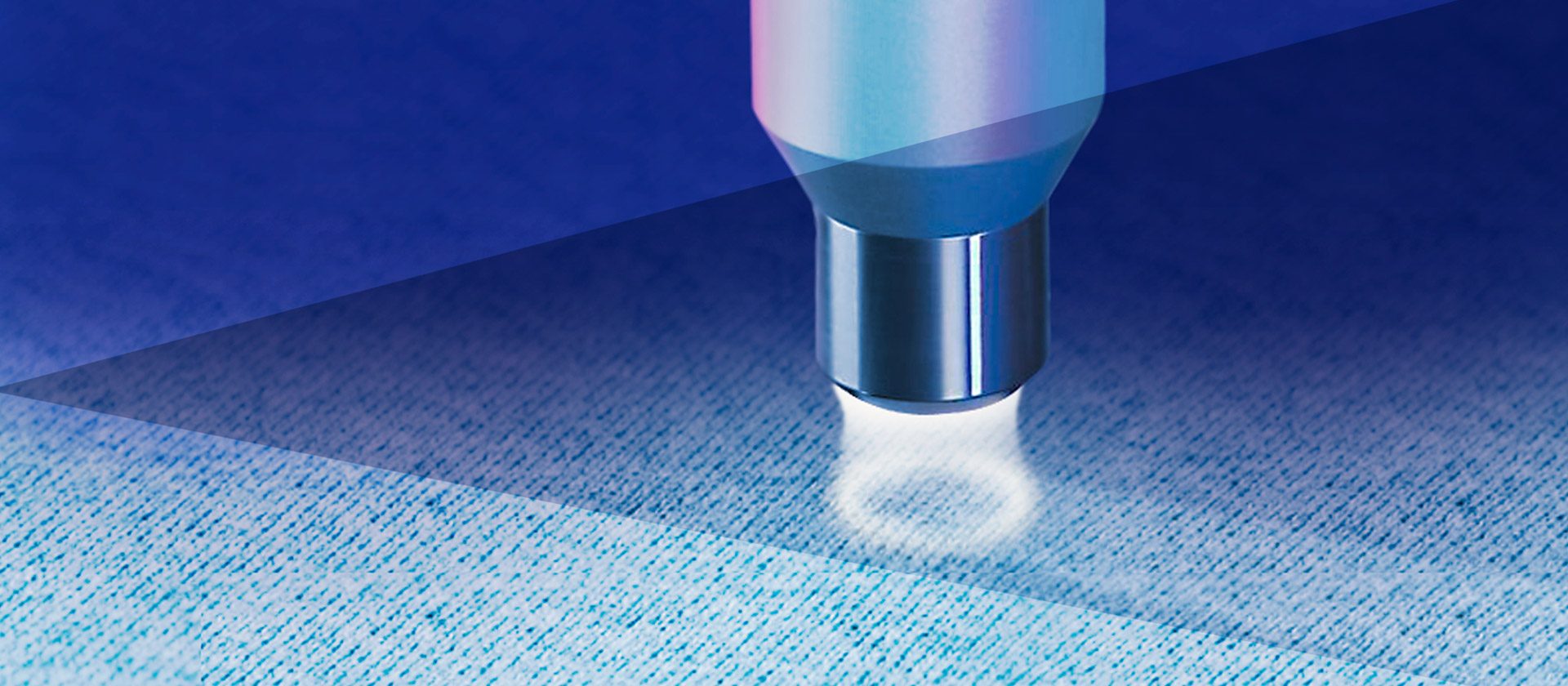

Atmospheric plasma enables altering properties of materials by replacing different processes of surface preparation thanks to the production of gaseous radicals, in-line deposit of nanometric layers, and variations of roughness on a nanometric scale.

Surface treatments with atmospheric plasma

Atmospheric plasma is particularly interesting for industries and production processes as it does not require vacuum chambers and can therefore be easily sized and introduced directly into the production lines. A high-voltage, medium-frequency AC generator allows the gas to be ionized at atmospheric pressure.

Atmospheric plasma is characterized by the production of gaseous radicals that cause the cleaning and generation of an active state of the surfaces. Some examples include degreasing, increased dyeing performance of fabrics, increased capacity of adhesion and coupling of various materials and even sterilization of biological materials.

Atmospheric plasma also allows an in-line deposit of nanometric layers on the surfaces of materials to alter their properties such as hydro- and/or oil-repellency, development of antifouling properties, controlled drug release, smoke absorption, flame resistance and stain-resistant properties of tissues.

Finally, atmospheric plasma enables altering the surface of a material by modifying its roughness on a nanometric scale. This modification increases the cohesion between the fibers of fibrous materials, thus increasing dimensional stability.

At Inovalab we have expertise in atmospheric plasma technology that allows us to support our customers in the innovation of their industrial processes with a reduction in production time and costs, improving product performance through the introduction of new technologies. Once the process has been determined, we are able to design and produce the prototype of the plasma machine that meets the customer’s needs.